In the field of plastic product production and processing, ultrasonic welding has become the preferred connection method for many companies due to its advantages such as high efficiency, environmental protection, and no need to add additional materials. However, to achieve ideal welding results, it is essential to have a deep understanding of the characteristics of plastics.

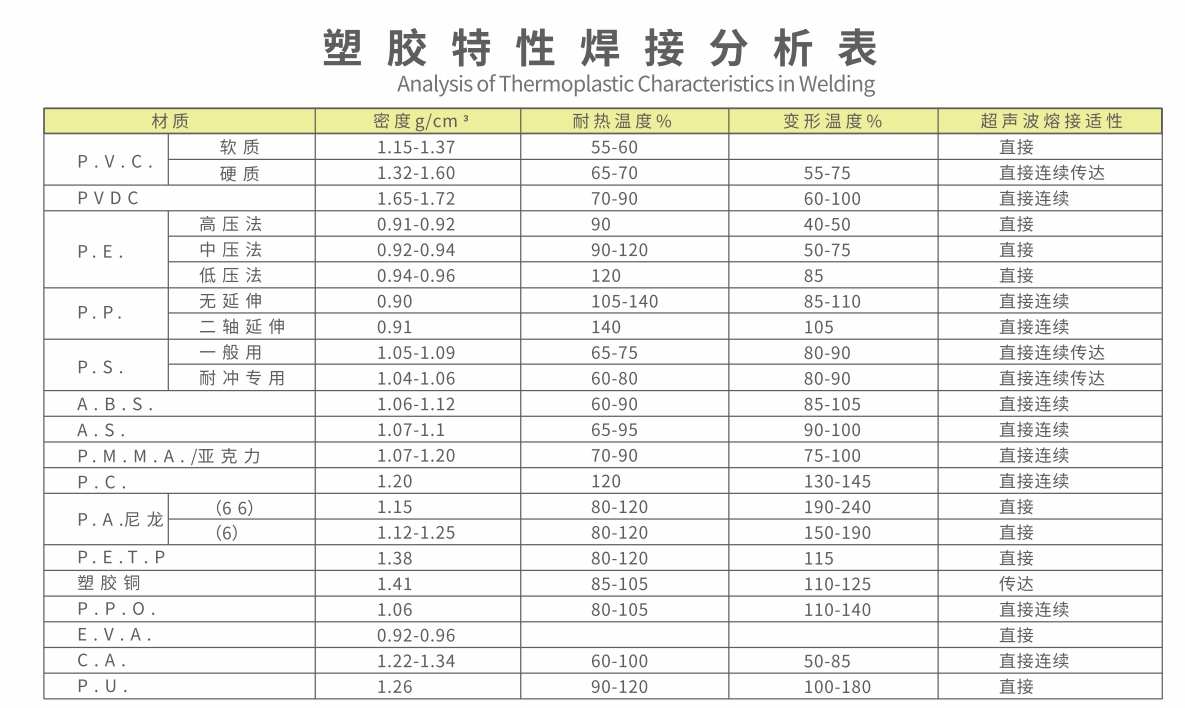

The material, density, heat resistance temperature, deformation temperature and other characteristics of plastics will have a significant impact on ultrasonic welding. For example, in terms of material, PVC is divided into soft and hard. The density of soft PVC is 1.15-1.37g/cm³, the heat resistance temperature is 55-60℃, the deformation temperature range is 55 - 75℃, and its ultrasonic welding adaptability is direct welding; while the density of hard PVC is 1.32 - 1.60g/cm³, the heat resistance temperature is increased to 65 - 70℃, the deformation temperature is also 55 - 75℃, and the welding adaptability is direct continuous transmission. This shows that when welding PVC of different hardness, there are differences in the absorption and conduction of ultrasonic energy, and the welding parameters need to be adjusted according to their characteristics.

Looking at PVDC, the density of PVDC produced by high pressure method is 0.91 - 0.92g/cm³, the heat resistance temperature is 90℃, the deformation temperature is 40 - 50℃, and it can be directly ultrasonically welded. The density of PE material produced by medium pressure method is 0.92 - 0.94g/cm³, the heat resistance temperature is 90 - 120℃, the deformation temperature is 50 - 75℃, and it is also suitable for direct welding. These characteristic data provide important basis for selecting appropriate welding process.

In addition, materials such as PA nylon, PETP, and plastic copper also have their own unique plastic properties. For example, PA and nylon have a density of 1.12 - 1.25g/cm³, a heat resistance temperature of 80 - 120℃, and a deformation temperature of 150 - 190℃, and can be directly welded; PETP has a density of 1.38g/cm³, a heat resistance temperature of 80 - 120℃, and a deformation temperature of 115℃, and can also be directly welded. Understanding these characteristics can help us accurately set welding parameters when welding different materials to ensure welding quality.

In actual production, choosing the right ultrasonic welding machine is also critical. As a professional ultrasonic welding equipment manufacturer, apsonic ultrasonic, with years of technical accumulation and industry experience, can provide you with high-quality, high-performance ultrasonic welding machines. Our equipment fully considers the characteristics of various plastics, has precise welding parameter adjustment functions, and can meet the welding needs of different materials and different products. Choosing an apsonic ultrasonic welding machine means choosing an efficient, stable and reliable welding solution, which will make your production smoother and product quality more guaranteed.